| Back to Index |

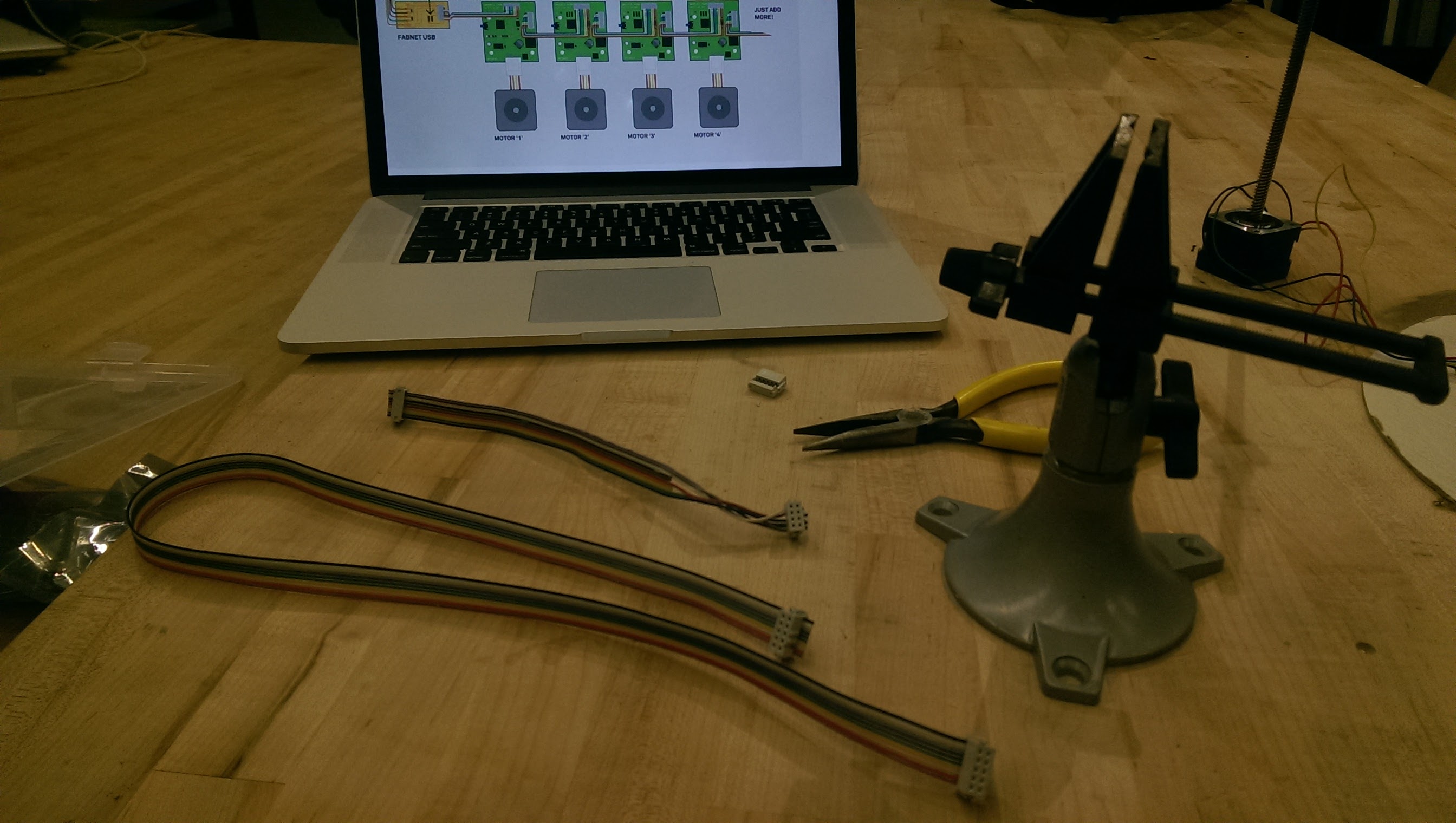

I arrived to the shop ready to work! Coding wasn't my strong suit, though I figured that'd happen later on. I was hoping for some physical task, and I got two: replicate some cabling, and help assemble the cardboard frames. First, cables!

I needed to make 3 of the 2 x 5 cables, and one of the more complicated 2 x 5 to 2 x 4. The 2 x 5s were pretty straight-forward, though the vice I was using was plastic, bendy, squeaky, and not terribly good.

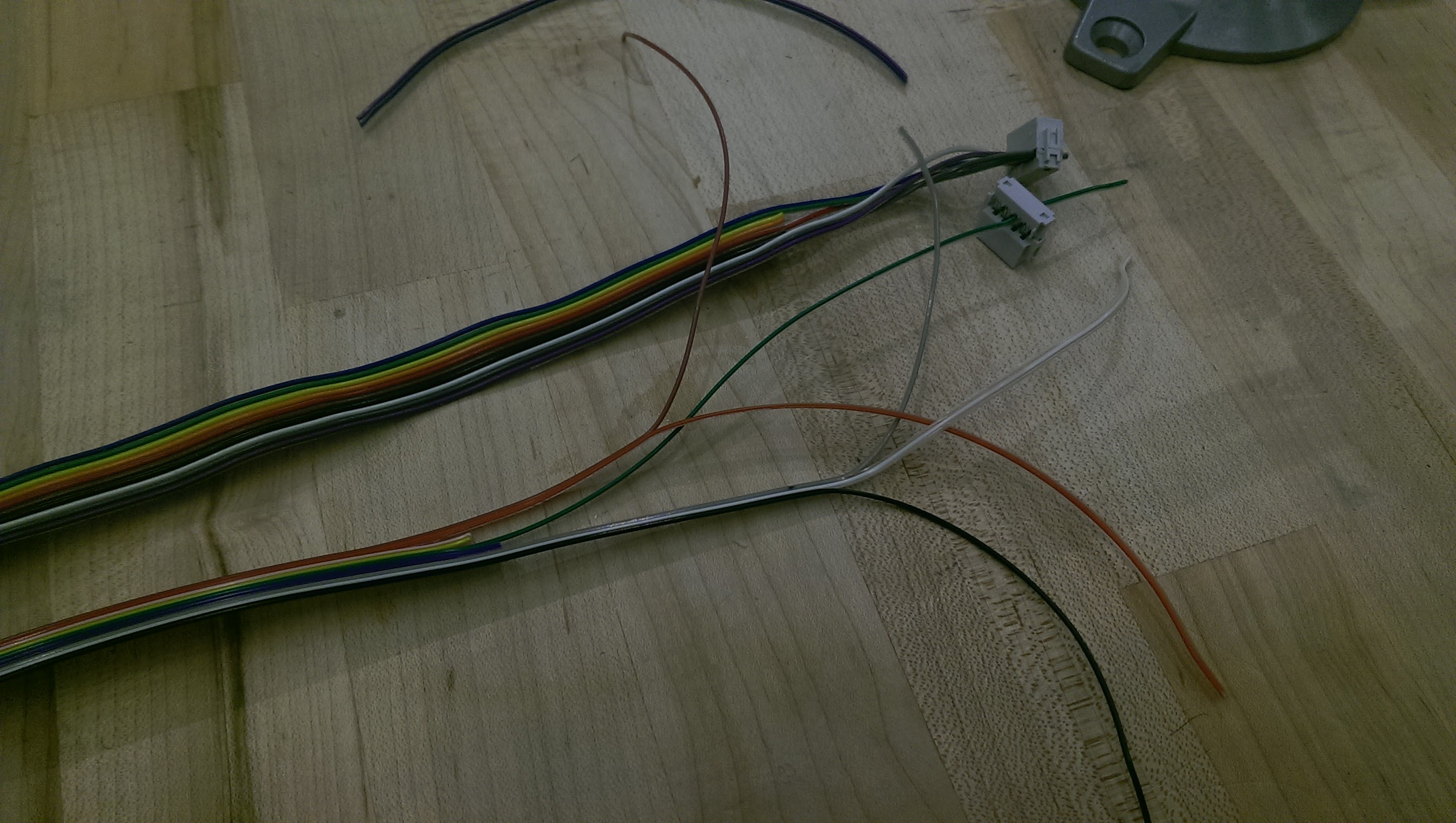

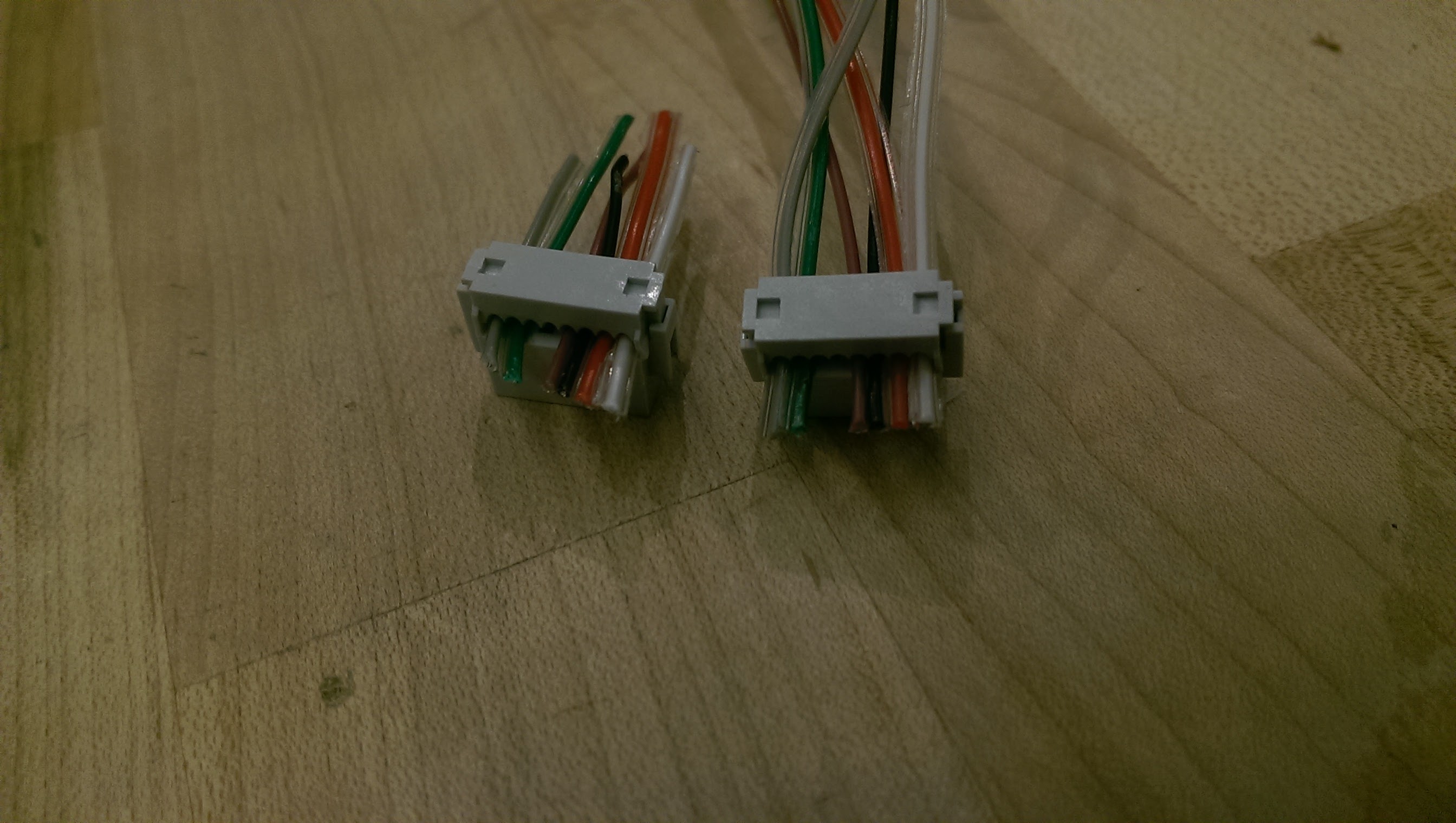

The 2 x 5 to 2 x 4 (with only 5 very specifically placed wires) was more of a challenge. I had to separate the different colored wires, and make sure the proper ones got pinned into the proper slots on the harness.

I accidentally made a mirror of what I needed to make, and I thought I corrected it, but looking back on this picture (and remembering an email where someone complained that one of the cables didn't work), I'm thinking I made the same mistake twice. (Sorry!)

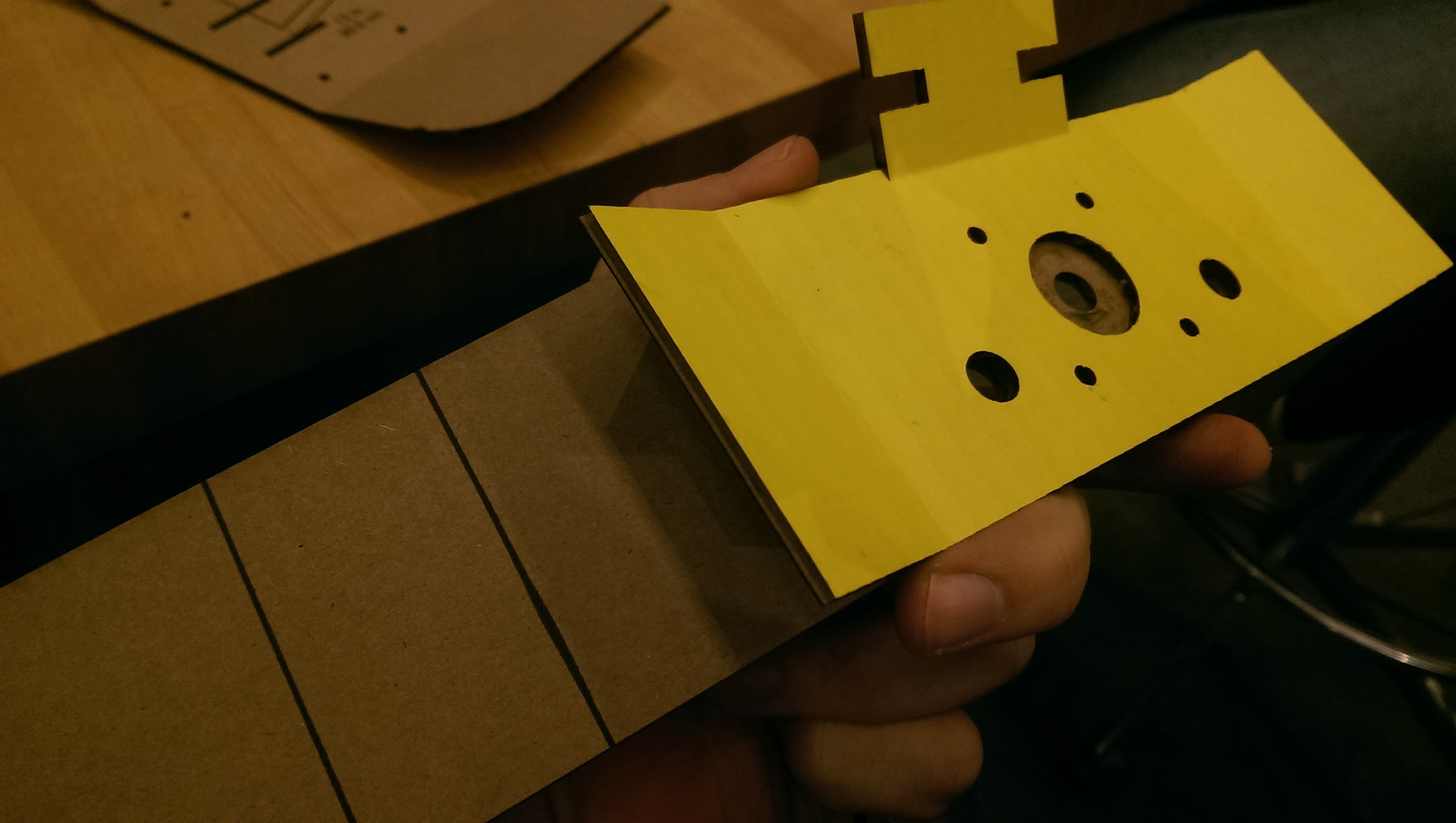

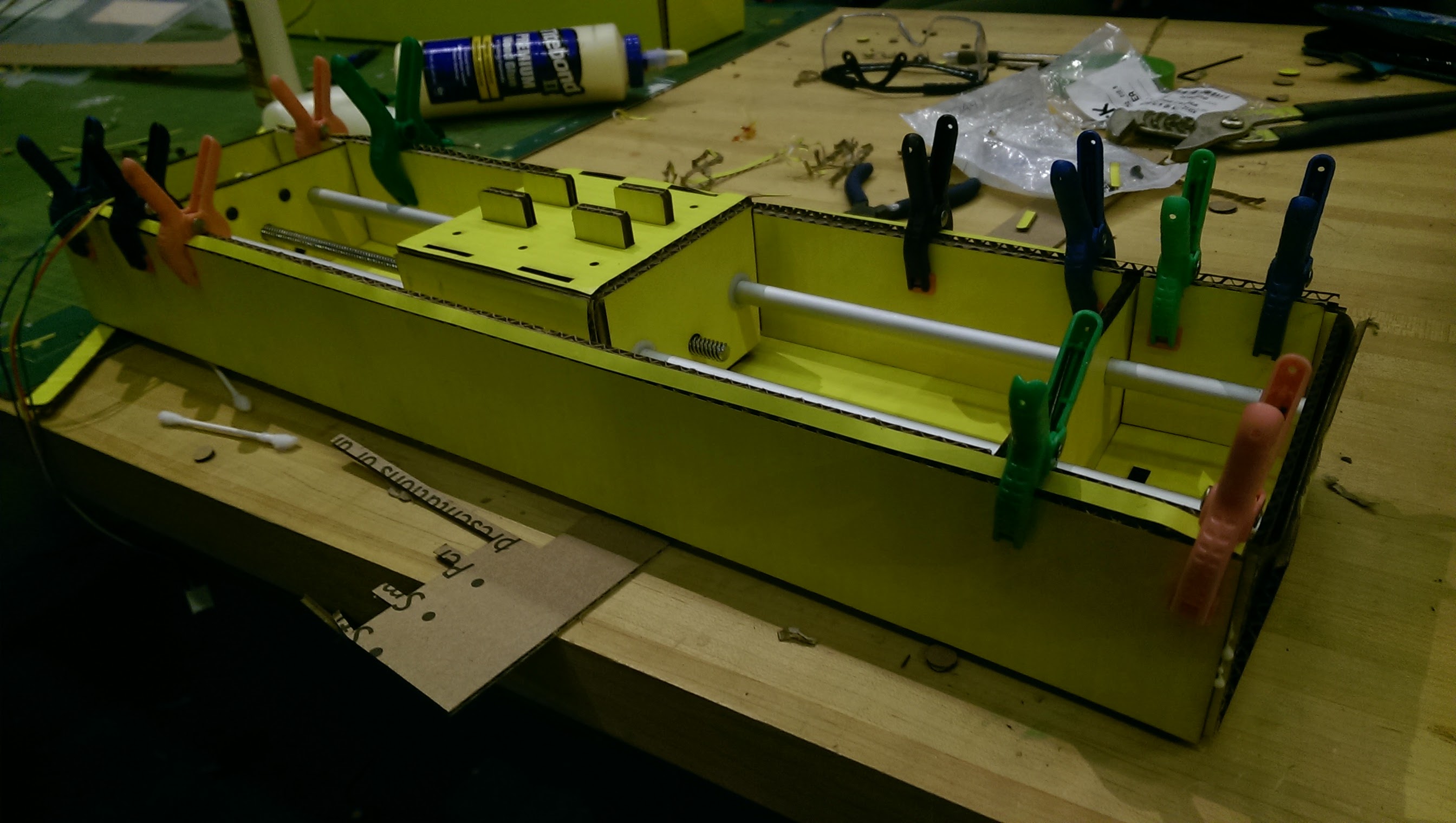

Having thought I did my job well, I turned to helping out assembling the cardboard frame for the machine. There were some hidden pieces on the ends that added necessary thickness that we left out a couple times, but eventually we got all the pieces involved lined up correctly, using the front-facing yellow as hints.

We clamped it all together ...

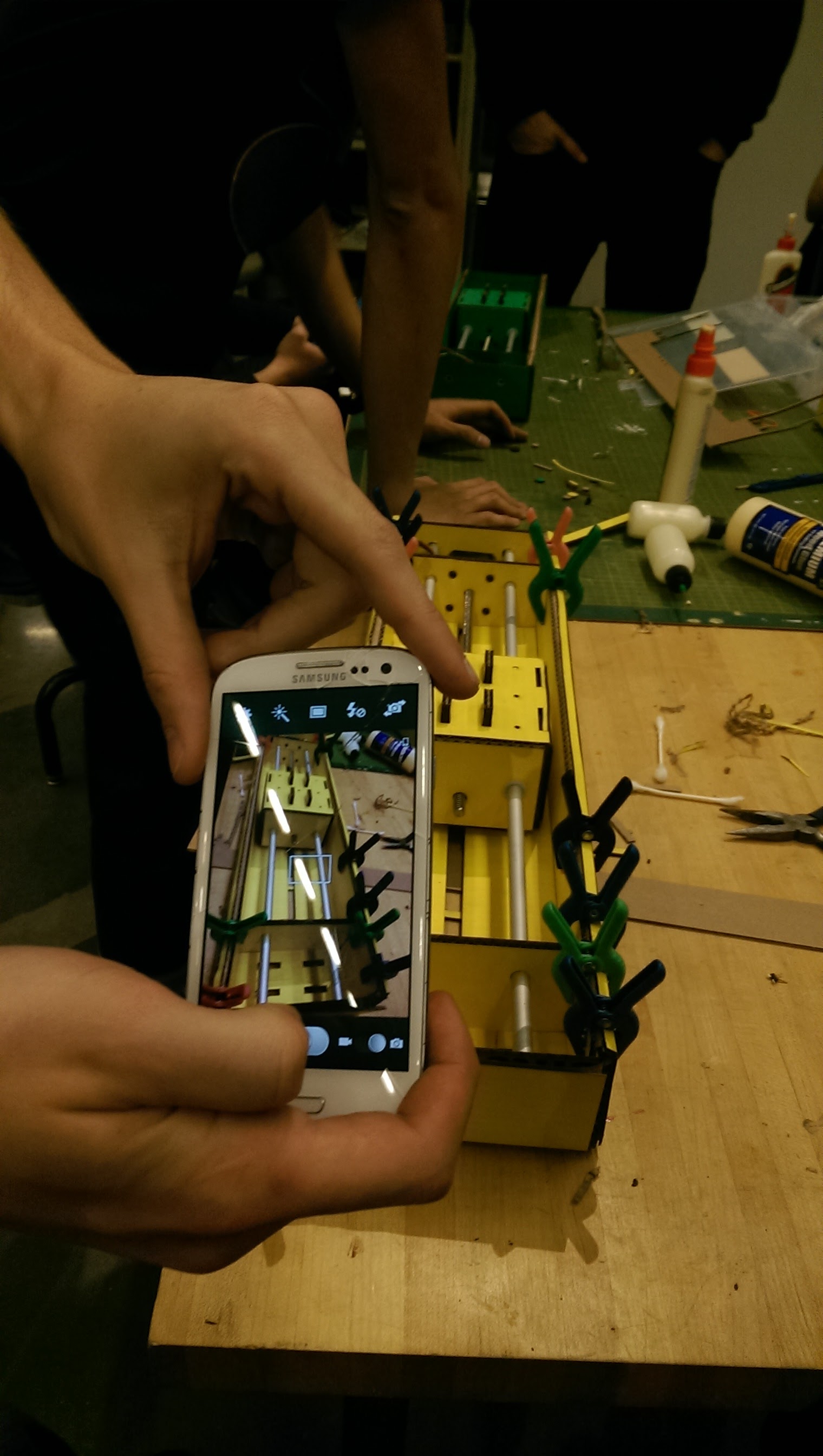

Took pictures for posterity ...

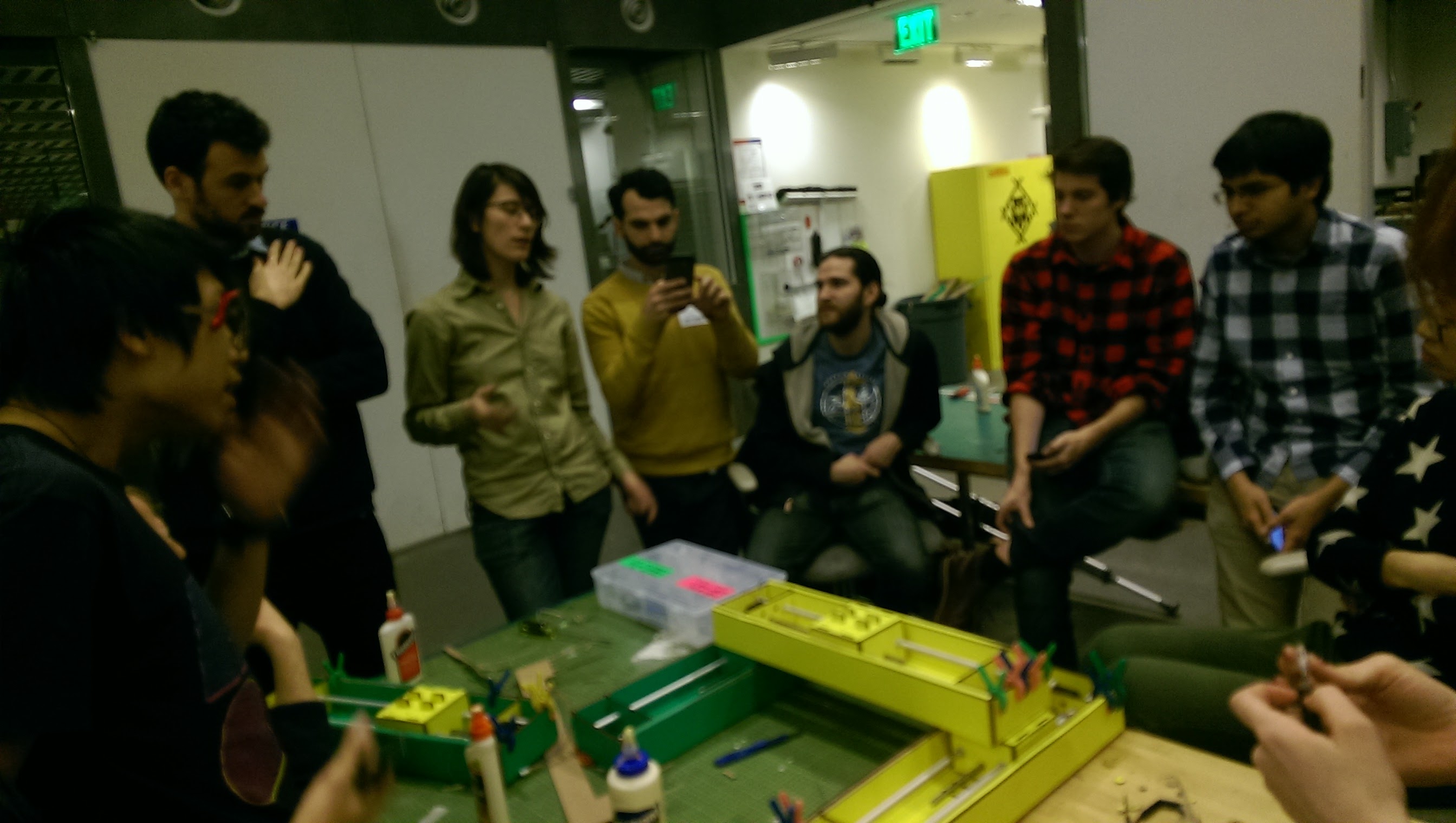

And joked about possible uses (a tattoo gun!) over a tentative final assembly.

I had to dedicate the rest of my weekend for a final project for another class, and was unable to participate in the "make the machine make something" part of making a machine that makes. But I was excited to be able to fully dedicate my time to my final project!